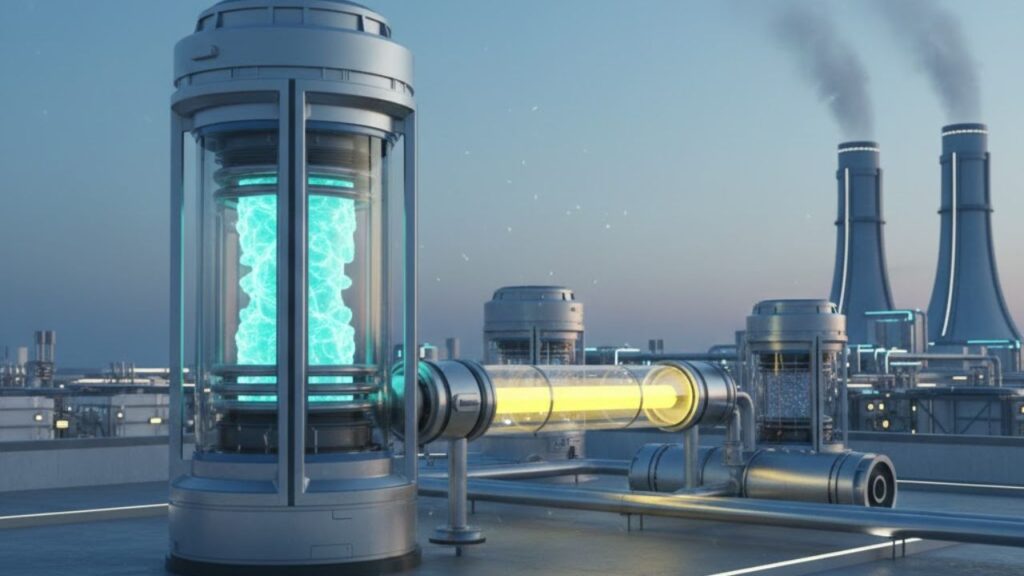

China has unveiled a breakthrough industrial technology that could quietly reshape how factories use energy. Researchers have developed a non-rotating heat pump that converts sound waves into usable heat, targeting one of the biggest problems in heavy industry: wasted thermal energy. In a country like China, where manufacturing remains central to economic growth, recovering lost heat could significantly cut emissions and energy costs. Early tests suggest this sound-based system could reclaim up to 27% of industrial waste heat, offering a cleaner, more efficient alternative to conventional mechanical heat pumps.

China’s non-rotating heat pump changes industrial energy recovery

Traditional heat pumps rely on compressors, moving parts, and constant mechanical motion, which makes them expensive to maintain and prone to wear. China’s new approach flips that idea by using acoustic waves instead of rotation. By channeling sound through specially designed chambers, the system generates temperature differences without mechanical stress. This design enables no moving components, lower maintenance costs, and stable long-term operation. Engineers also highlight industrial waste heat recovery as the main advantage, especially in steel, cement, and chemical plants. Because the system avoids friction-heavy parts, it can operate in harsher environments where traditional pumps fail, making it particularly attractive for large-scale industrial deployment.

Sound-based heat pump technology targets wasted industrial heat

At the heart of this innovation is thermoacoustic science, where sound waves drive heat transfer through pressure oscillations. When tuned correctly, these waves push heat from cooler areas to warmer ones, effectively acting as a pump. The Chinese prototype focuses on acoustic energy conversion, allowing factories to reuse heat that would otherwise escape into the air. Developers claim energy efficiency gains of up to 27%, a figure that could translate into massive savings at scale. With simplified system design and reduced mechanical losses, the technology offers a fresh path for industries struggling to meet energy efficiency and emissions targets.

Why China’s acoustic heat pump matters for global industry

China’s industrial sector is one of the world’s largest energy consumers, so even small efficiency improvements can have global impacts. This non-rotating heat pump could support carbon reduction goals while maintaining productivity. Unlike experimental lab concepts, this system is designed for real factories, emphasizing scalable industrial deployment and compatibility with existing plants. Analysts also point to manufacturing cost control as a key factor, since fewer moving parts often mean cheaper production. If adopted widely, the technology could inspire similar solutions worldwide, helping industries recover heat rather than burning more fuel to replace it.

Goodbye to Old Licence Rules: Older Drivers Face New Renewal Requirements From February 2026

Goodbye to Old Licence Rules: Older Drivers Face New Renewal Requirements From February 2026

What this breakthrough means for the future of energy use

This development signals a shift in how engineers think about efficiency. Instead of optimizing old mechanical systems, China’s researchers are reimagining energy transfer itself. The idea of turning sound into heat may sound abstract, but its implications are practical and immediate. With long-term reliability, lower operational risk, and significant energy savings, the technology could become a cornerstone of next-generation industrial infrastructure. While further testing and scaling are still needed, this approach highlights how unconventional physics can solve very real energy problems, especially in energy-intensive economies.

| Feature | Traditional Heat Pump | Non-Rotating Heat Pump |

|---|---|---|

| Core Mechanism | Mechanical compression | Sound-based transfer |

| Moving Parts | Multiple components | None |

| Maintenance Needs | High | Low |

| Waste Heat Recovery | Limited | Up to 27% |

Frequently Asked Questions (FAQs)

1. What makes this heat pump “non-rotating”?

It uses sound waves instead of rotating mechanical parts to move heat.

2. How much energy can the system recover?

Tests suggest it can reclaim around 27% of industrial waste heat.

3. Which industries could benefit most?

Steel, cement, and chemical manufacturing are key potential users.

4. Is this technology ready for mass adoption?

It shows strong promise but still requires large-scale industrial trials.