In a breakthrough that sounds like science fiction, researchers in the United States have developed liquid gears that can transmit motion without ever touching or using traditional teeth. Instead of rigid metal parts grinding together, these systems rely on carefully controlled fluid dynamics to move energy smoothly and precisely. The idea challenges centuries of mechanical design and opens doors to quieter machines, reduced wear, and entirely new applications. From advanced robotics to medical devices, this innovation shows how rethinking old problems with modern science can reshape the future of motion control.

Liquid gears technology redefining motion transfer

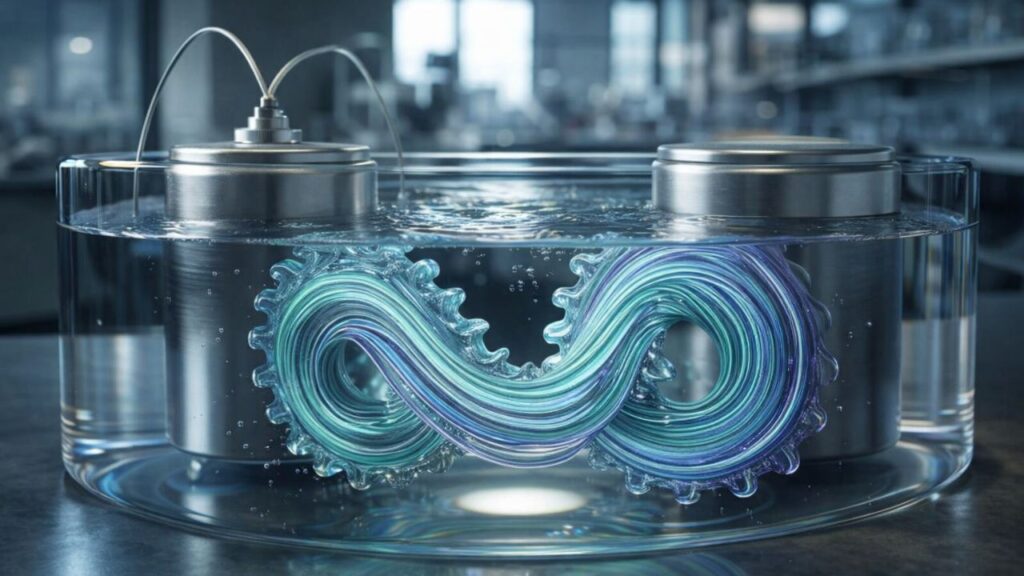

Liquid gears work by shaping and directing fluids so they behave like solid components, allowing motion to pass from one part to another without contact. This approach eliminates friction points that usually cause wear and noise. Engineers describe it as contact-free motion driven by fluid-controlled forces rather than metal teeth. Because there is no physical grinding, systems can last longer and require less maintenance. Another advantage is adaptability; the shape-shifting medium can respond to changes in load instantly. For industries seeking precision, the promise of smooth energy transfer and reduced mechanical stress is extremely attractive.

Touchless liquid gear systems and how they work

At the heart of these systems is the careful manipulation of pressure, viscosity, and flow patterns. By tuning these variables, researchers create pressure-driven rotation that mimics traditional gears. Sensors and algorithms ensure real-time responsiveness, allowing the liquid to adjust instantly as conditions change. This results in silent operation that is ideal for sensitive environments. The lack of rigid contact also means fewer failures, supporting longer system lifespan. What makes this especially exciting is the potential for scalable design concepts, from tiny lab instruments to large industrial machines.

Future applications of liquid-based gear mechanisms

The potential uses of liquid gears extend far beyond factories. In medicine, they could enable ultra-precise movement inside surgical tools, reducing patient risk. Robotics may benefit from adaptive motion control that reacts smoothly to human interaction. Renewable energy systems could use them for low-maintenance power transfer in harsh environments. Because these gears can be sealed, they also offer contamination-free operation. As research progresses, experts believe this technology could support next-generation machines that are quieter, safer, and more efficient than anything built before.

Why liquid gears could change engineering

For centuries, mechanical engineering has depended on solid parts making contact. Liquid gears challenge that assumption by proving motion does not require teeth or touch. This shift encourages designers to think differently, focusing on behavior rather than form. With benefits like lower friction losses, minimal wear issues, and enhanced design freedom, the concept could influence how future engineers are trained. While still emerging, early tests suggest strong reliability and efficiency. If scaled successfully, liquid gears may become a cornerstone of modern mechanical innovation, reshaping how machines are built and maintained.

| Feature | Traditional Gears | Liquid Gears |

|---|---|---|

| Physical Contact | Required | Not required |

| Noise Level | Moderate to high | Very low |

| Maintenance Needs | Regular lubrication | Minimal upkeep |

| Wear Over Time | Common | Significantly reduced |

| Design Flexibility | Limited shapes | Highly adaptable |

Frequently Asked Questions (FAQs)

1. What are liquid gears?

They are motion-transmission systems that use controlled fluids instead of solid gear teeth.

The one winter fruit that keeps robins coming back to your garden, according to birdwatchers

The one winter fruit that keeps robins coming back to your garden, according to birdwatchers

2. Do liquid gears replace traditional gears completely?

No, they complement existing designs and suit specific applications requiring low friction and noise.

3. Where are liquid gears most useful?

They are ideal for robotics, medical devices, and precision machinery.

4. Are liquid gears commercially available?

Most designs are still in research and testing, with commercial use expected in the future.